Project Details

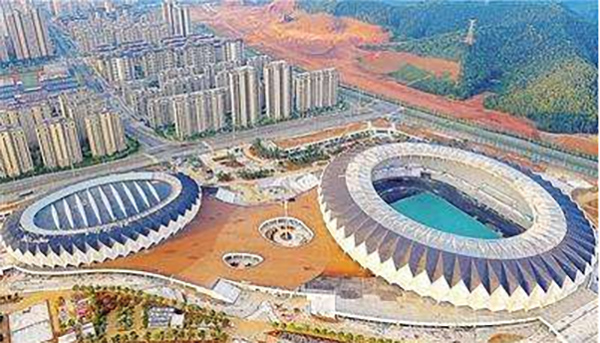

Building area: 48702m2 (building area: 36876m2, canopy building area: 11826m2)

Construction area: 50445m2

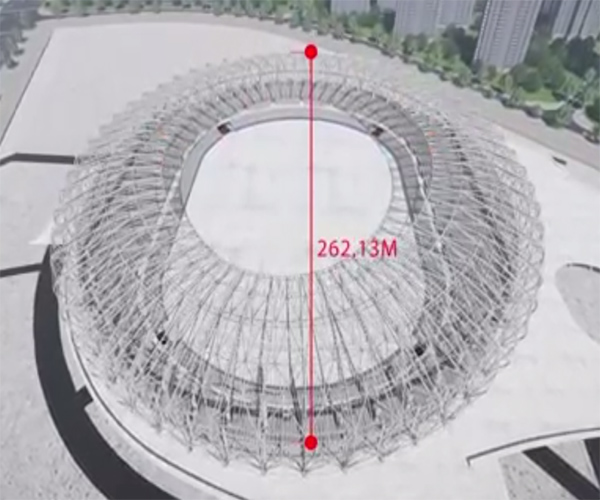

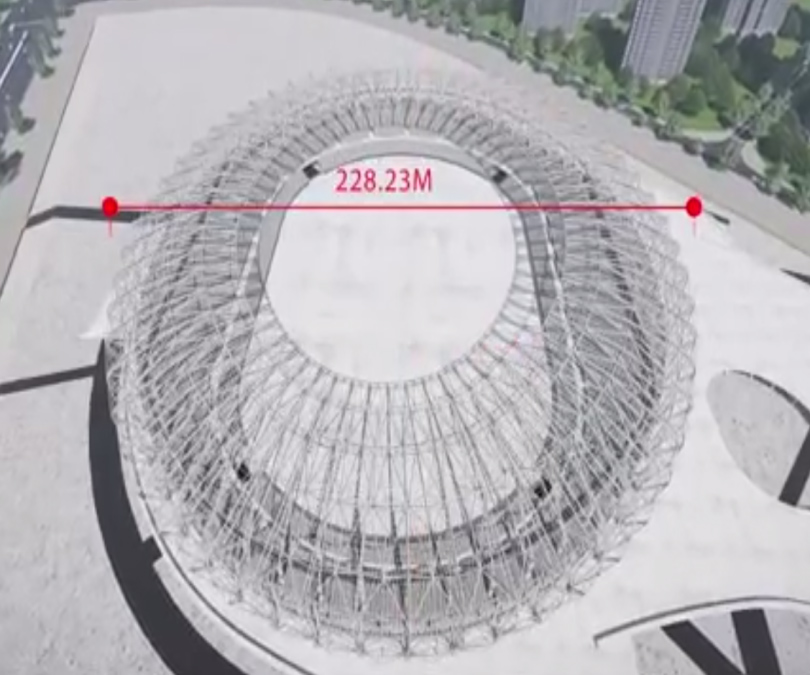

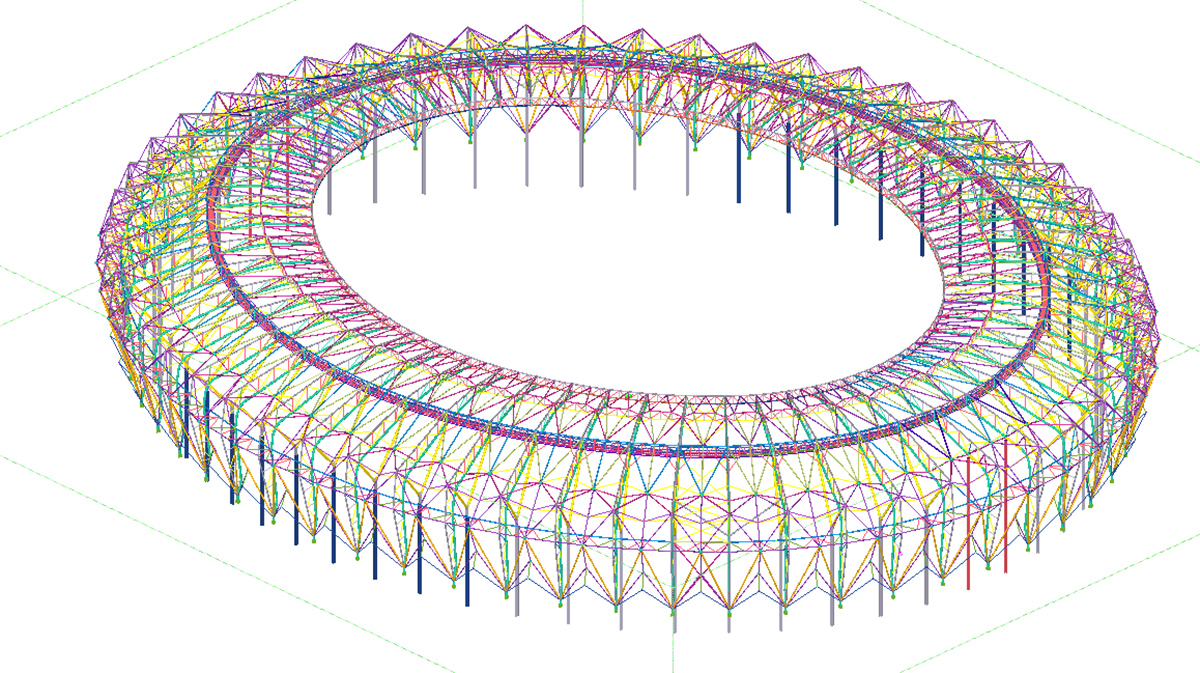

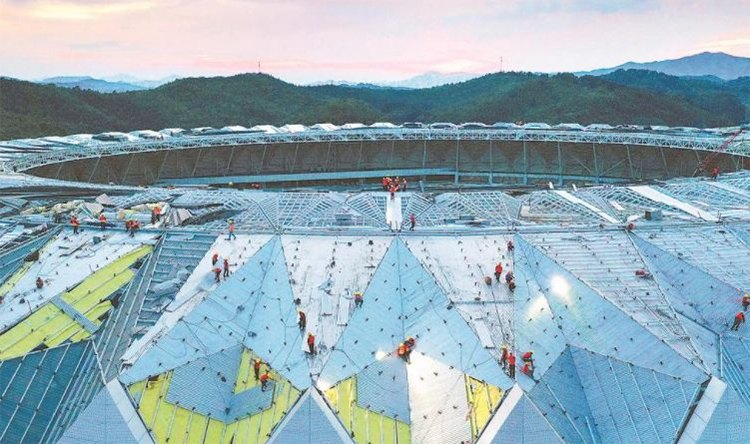

The number of building layers of the stadium: main body 1 layer, local 3 layers; Height (average height from outdoor floor to eaves and ridges) : 62m. Interior concrete building height: 42.80m (height difference between indoor and outdoor is 0.30m); The plane shape is concentric elliptic ring. The total tonnage is 12,000 tons.

Building area: 48702m2 (building area: 36876m2, canopy building area: 11826m2)

Construction area: 50445m2

The number of building layers of the stadium: main body 1 layer, local 3 layers; Height (average height from outdoor floor to eaves and ridges) : 62m. Interior concrete building height: 42.80m (height difference between indoor and outdoor is 0.30m); The plane shape is concentric elliptic ring. The total tonnage is 12,000 tons.

How to prevent the truss from instability and excessive deformation in the process of lifting is the key point of this scheme. It is also the key to ensure the whole project duration and quality.

1) Consider a variety of lifting methods, choose the best first. And formulate detailed lifting measures.

2) Before hoisting, calculate and analyze the steel wire rope selected for hoisting. Ensure to meet the lifting capacity.

3) Set two inverted chains on the same side of the hanging rope to adjust the air attitude of the truss.

(4) When the main truss and the secondary truss are installed at high altitude, the safety of the installation process of the steel structure is the key point of the project construction. When the main truss, secondary truss and ring truss are installed at high altitude, temporary walkways, hanging baskets and other auxiliary facilities are set up to facilitate high altitude welding, as shown in the figure below, and safety nets and safety ropes are hung to ensure the safety of steel structure installation process.

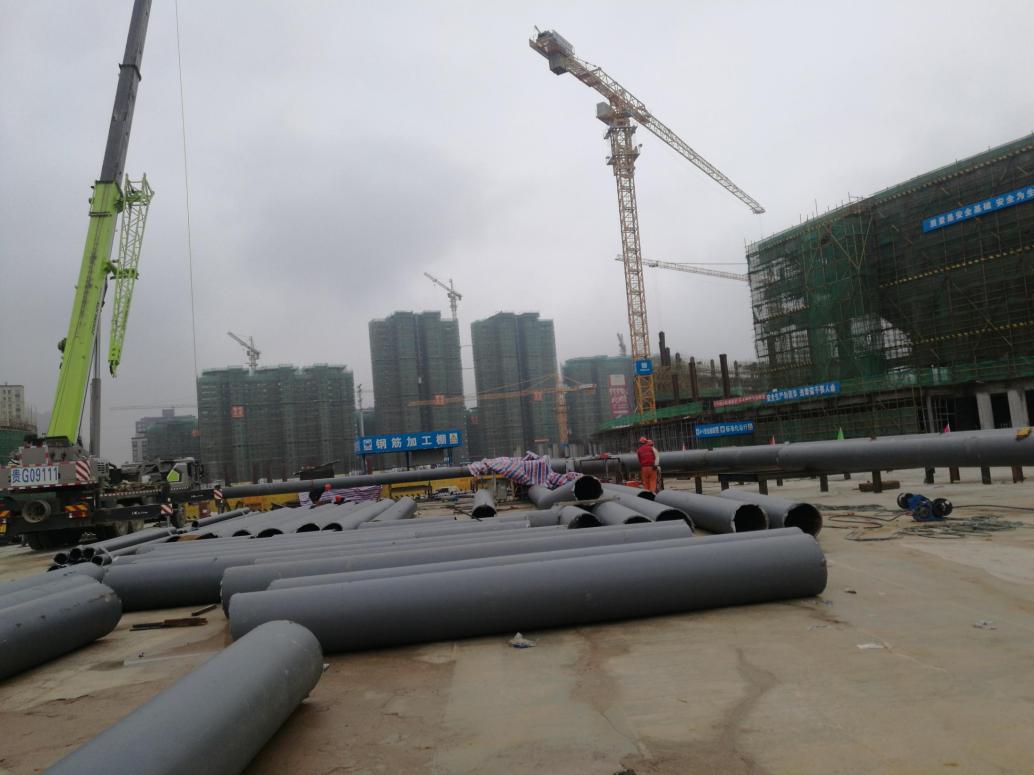

(5) The component section is large, and the weight of the monomer is heavy. One of the stadium trusses weighs 53 tons. At the same time, limited by the site conditions and building structure, the crane can not be close to the hoisting, which brings great difficulties to the site transportation, positioning, turning over and later hoisting of components. To this end, we use a number of 350T crawler cranes for construction.

(6) Large amount of engineering, tight construction period, multi-work cross-work is one of the prominent difficulties of the project. To this difficulty the company will pull out the elite force to establish a strong team, strengthen the construction management. Optimize the construction plan, organize the construction team with strong technical force. Strengthen coordination among different types of work. Logistics support.

The steel frame was made on site, and the trusses were assembled with THREE-DIMENSIONAL positioning.

All the 56 trusses in the project are provided with a lattice column support frame at the end of the cantilever, with a height of 60 meters.

There is a reverse support under the grandstand

350T and 150T crawler cranes

Post time: Dec-29-2021