Project Details

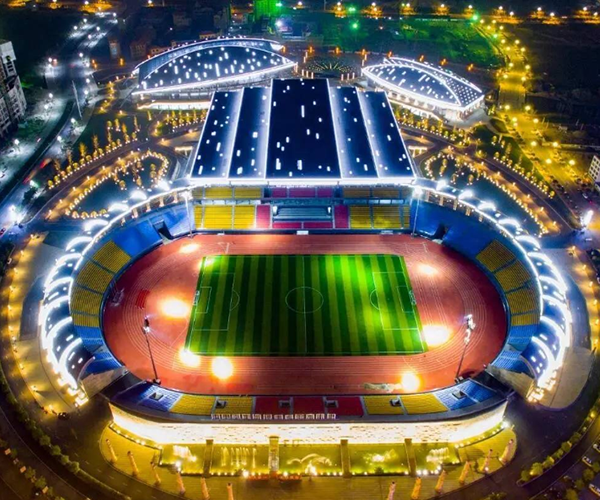

Project location: Xingyi Avenue, Xingyi City, Guizhou Province

Construction scale: 120,000 square meters

Project cost: The total investment is about 1.3 billion

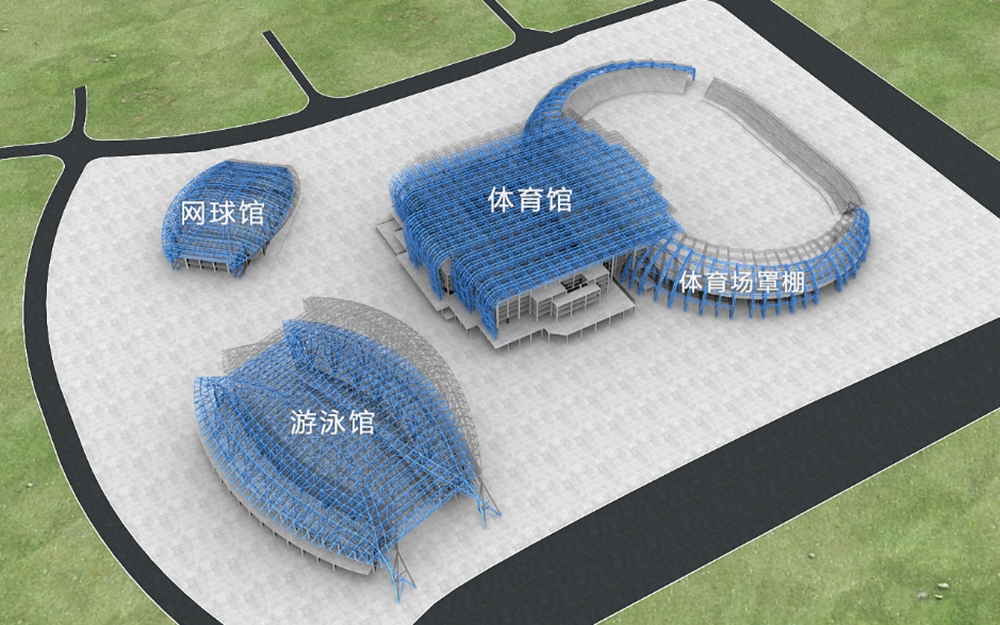

The steel structure is divided into three pavilions (gymnasium, tennis hall, natatorium and stadium canopy). The structure type is tube truss roof + local stiffening column. The total construction area of the stadium and gymnasium is 49,023.18 square meters, with two floors underground and four floors above ground.

Natatorium construction area of 19,600 square meters; Tennis hall construction area of 7200 square meters. The total height of the building is 64.2 meters.

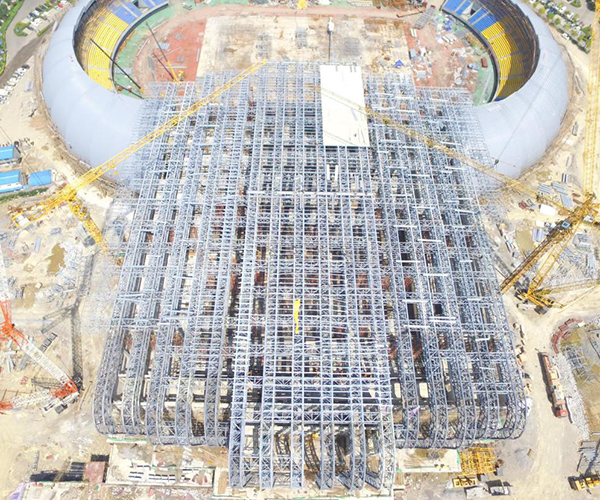

The stadium roof is square, with total length of 144.96 meters, total width of 122.7 meters, and height of 64.2 meters. There are 18 trusses in the main truss, 306 trusses in the secondary truss, and the maximum span of the truss is 142 meters.

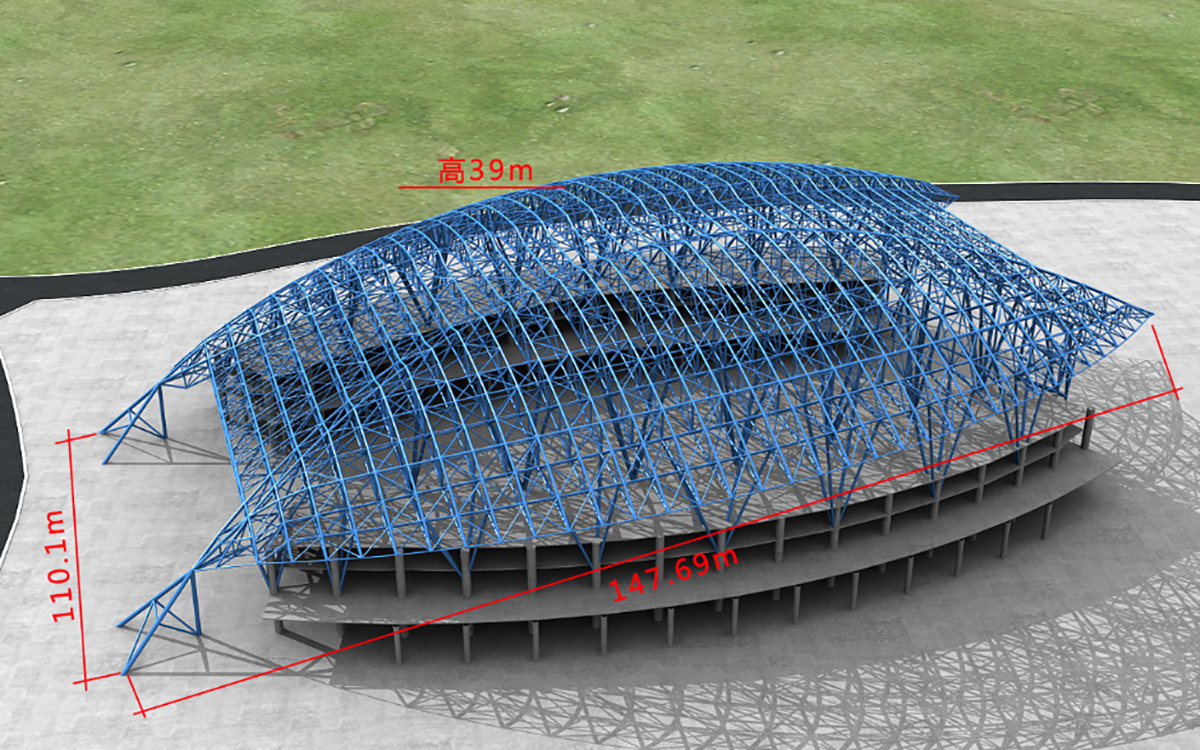

The natatorium roof is a hyperboloid semi-ellipse with total length of 147.69 meters, total width of 110.1 meters and height of 39 meters. 16 trusses for the main truss and 32 trusses for the secondary truss.

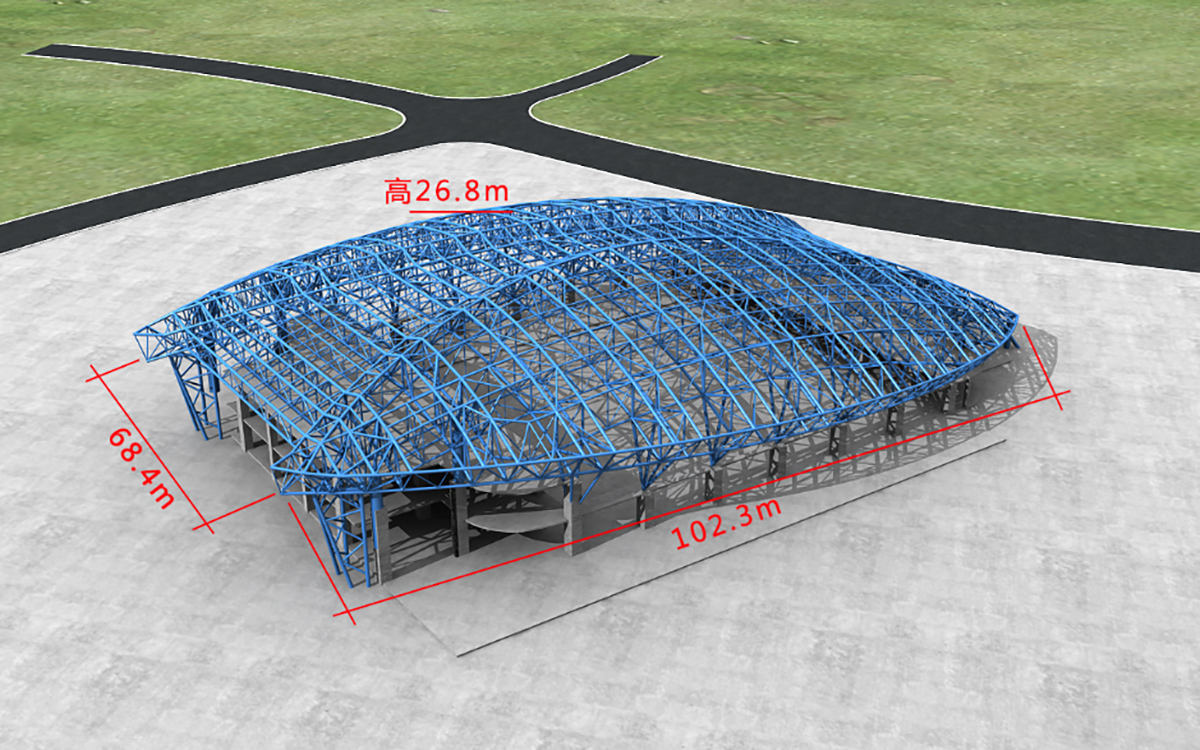

The pavilion is a hyperboloid semi-ellipse with a total length of 102.3 meters, a total width of 68.4 meters and a height of 26.8 meters. There are 12 main trusses and 39 secondary trusses.

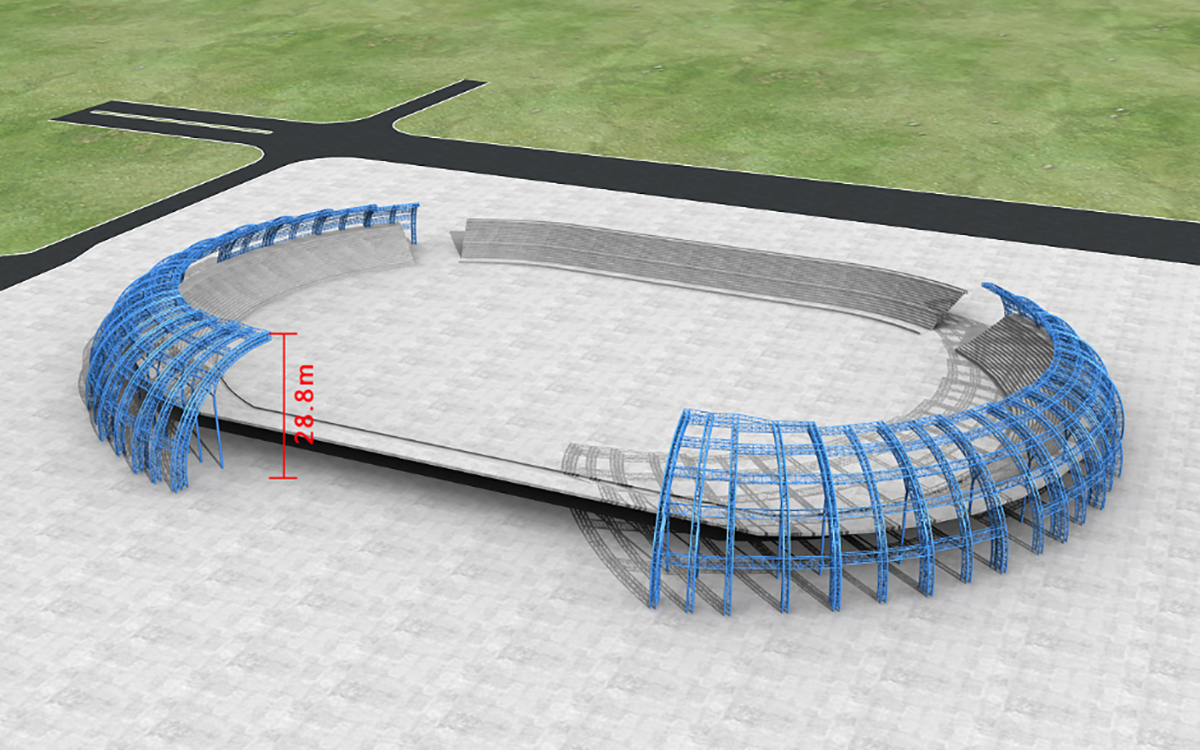

The stadium canopy is a "horn" shaped steel roof frame with a total length of 144.96 meters, a total width of 122.7 meters, and a height of 48.8 meters. There are 52 trusses in the main truss and 242 trusses in the secondary truss.

Difficulties:

Heavy workload of component installation, tight construction period, the construction period is about 40 days, about 842 pieces of assembly unit lifting need to be completed, how to complete the steel structure installation within the construction period is the focus of this project.

Solutions:

(1)Reasonable arrangement of material procurement -- component processing -- component approach -- component hoisting completion plan, strictly in accordance with the planned time node implementation, all components according to the installation zone gradually approach.

(2) Choose appropriate construction machinery, adopt reasonable construction technology, and adopt multiple crawler cranes and automobile cranes to enter the site for construction.

(3) Reasonably organize and allocate human and material resources to ensure the construction progress. Up to 365 people were used.

According to the selection of hoisting components and construction progress requirements, 2PCS 500T crawler cranes, 4PCS 350T crawler cranes and 1PC 150T crawler crane will enter the site gradually. In addition, various types of truck crane 15 PCS.

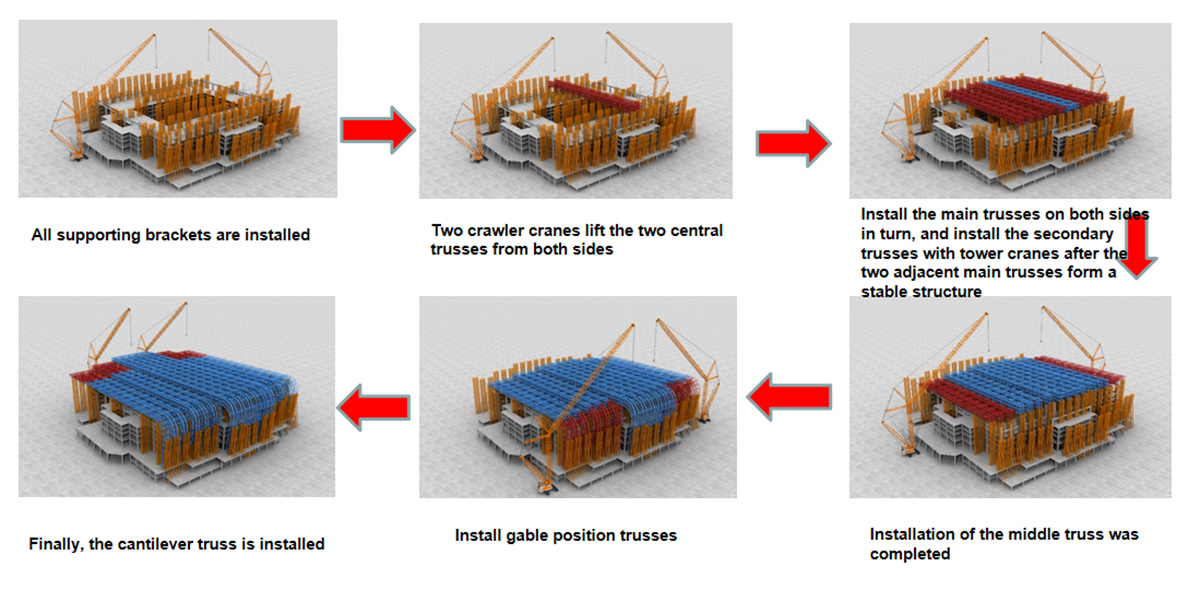

In order to implement the plan of segmentalized truss hoisting and high-altitude docking, it is necessary to set up the supporting bracket at the front to ensure, and to set up a temporary high-altitude supporting platform below each main truss segment point to meet the requirements of installation, and also to meet the requirements of high-altitude positioning and high-altitude welding of the main truss.

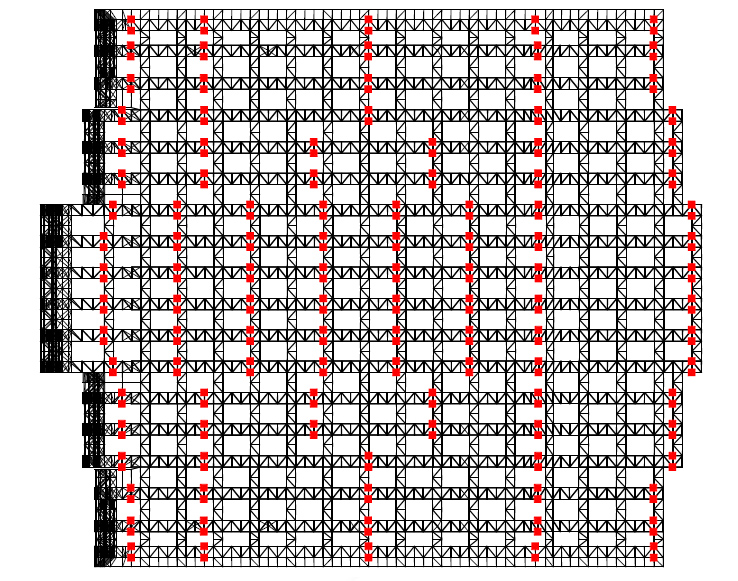

Temporary supports to be set up in the construction of gymnasium roof truss, please refer to "Temporary support layout" for the setting position of supports. Beret plate composite structure is adopted for supporting tire frame, and 224 temporary supporting tires are arranged in total.

The upper part is provided with an operating platform and a supporting tire rack. The cable wind rope should be set around the upper ground support frame to increase its stability after bearing, and the cable wind should be fixed on the concrete platform column or the ground anchor. The floor under the supporting bracket is reinforced with scaffolding.

A temporary support frame with a height of 60 meters and a total of 800T was set under the truss section during construction.

The site adopts steel assembling tire frame, three-dimensional positioning assembling.

Post time: Dec-29-2021